Evidence that the following journal paper is scientifically unsound

Characterization of the Core Properties of a Shock Absorbing Composite,

G. Georgiades, S.O. Oyadiji, X.Q. Zhu, J. R. Wright, and J.T. Turner,

Journal of Engineering Materials and Technology, ASME,

October 2007, Vol. 129, pages 497-504

This paper misquotes Bill Courtney's research and he calls for it to be retracted

Overview of the fraud

To the innocent eye this paper looks quite plausible. The electronic version sold well and the corresponding author was promoted.

But on closer inspection, the paper is self contradictory and meaningless.

It is mathematically correct, but the physical interpretation of the maths defies Newton's laws of motion and the laws of conservation of energy and conservation of momentum. There are other deficiencies including plagiarism of Bill Courtney's work and misquoting his research to mislead the reader..

The research was financed by the British taxpayer and was intended to assist Dow Chemicals in building a soft pedestrian friendly car bumper, to meet a pending EU Directive.

The unusual properties of the composite material meant that it could solve "The conflict of stiffness problem." That is, provide soft protection for pedestrian leg impacts, but stiffen up to protect the vehicle in other types of collisions.

In reality, Dow was unable to use the meaningless data and the joint project was abandoned.

There were no other solutions to the conflict of stiffness problem. So, following pressure from the car makers, the EU Directive was abandoned. Many thousands of European pedestrians are likely to have died or been permanently crippled as a consequence.

The paper was published in spite of written protests from Bill Courtney, the lead partner for the PedSALi (soft car bumper) project.

For proof that the paper was publish in breach of the confidentiality clauses of the legally binding PedSALi agreement please click.

The most unethical aspect of the paper is that it ends up misquoting Courtney's own research, falsely implying that the composite material (SALi) has poor impact recovery properties and was therefore unable to meet the EU Directives multiple impact requirements.

This falsehood is convenient for the authors and Manchester University, because it "absolves" them of any responsibility for the continuing pedestrian carnage on our roads. But it also helps to kill off any future research into SALi Technology.

This is a long web page. If your primary interest is in the misquoting of Courtney's research, you will need to scroll down to sections 6.6 and 6.7.

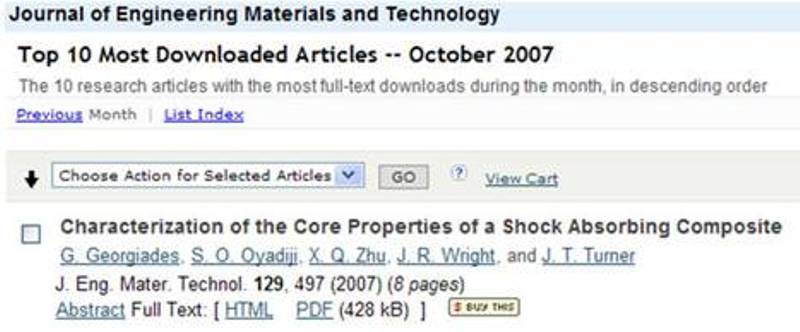

The electronic version of the paper was a best seller for the journal in October 2007 and still came in at number five in January 2008. Consequently a large number of researchers have been deceived by the fraud.

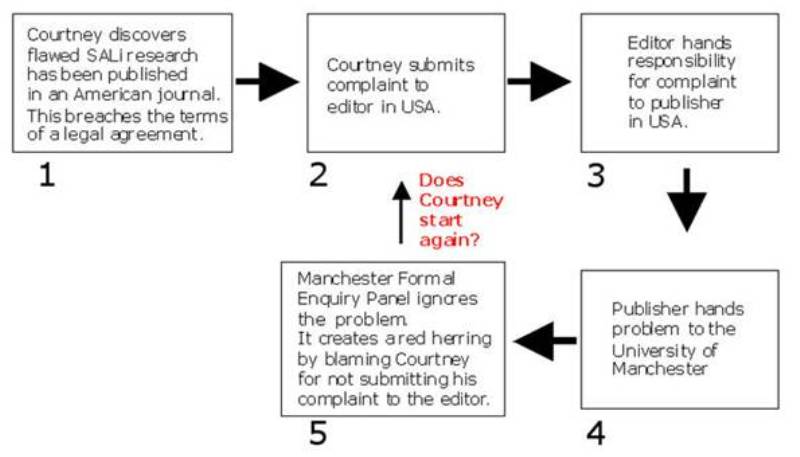

Courtney presented his evidence that the research was invalid to the Journal Editor and Publisher. He called for the paper to be retracted because it misled readers, damaged his intellectual property and gave false credit to the authors.

Unfortunately the problem was not clear cut, because the published paper included several embarrassing "howlers" .

These should have been picked up by the journal's referees at the peer review stage.

- Retraction would cast the journal as well as the authors, in a bad light.

After dragging their feet for fourteen months, the Publishers advised Courtney to raise his doubts directly with Manchester University.

Click to see the trail of email evidence.

Subsequently Courtney provided a Manchester University Formal Enquiry Panel with:(i) A history of the fraud problem including his dealings with the journal,

(ii) A copy of his letter to the Publisher in which the research case for retraction was spelt out in detail.

(iii) Proof that that the paper had been published in breach of agreement and under protest from Courtney.

The Panel refused to examine Bill’s evidence on the spurious grounds that

he had not contacted the journal first. This is a bizarre and dishonest excuse in the light of the evidence.

The excuse is convenient for the reputation of Manchester University, but shames British science.

Science will be reduced to science fiction if those charged with research quality control are allowed to pass the buck.

After reading the rest of this page, please challenge this buck passing behaviour if you value honesty in science.

People you can write to

The Research Governance and Integrity Manager at the University of Manchester is Mrs April Lockyer This email address is being protected from spambots. You need JavaScript enabled to view it.

The University of Manchester people on the panel were

Professor Helen Gleeson This email address is being protected from spambots. You need JavaScript enabled to view it.

Professor Peter Duck This email address is being protected from spambots. You need JavaScript enabled to view it.

The UK Research Integrity Office representative on the panel was Dr Pablo Fernandez

http://www.ukrio.org/get-advice-from-ukrio/

(Bill Courtney has written to the UK Research Integrity Office about this matter, but nobody was prepared to tackle such an embarrassing case of Formal Enquiry Panel fraud.)

THE CASE IN DETAIL

1 Evidence that the paper was a best seller:

Here is an extract from the journals top ten papers page:

2 Evidence that the best selling paper was a fraud

2.1 Legal fraud

The Panel was presented with detailed evidence that the paper had been published in breach of the collaboration agreement between Dow, Manchester University and Cheshire Innovation (Bill’s trading name).

Proof of the legal breach was presented to the Panel as Document D2. Please ask Manchester University for a copy.

2.2 The research fraud

Document D1 reproduced below provides testable evidence of:

- Plagiarism of an unpublished research paper written by Courtney.

- Falsely claiming credit for Courtney's work upgrading the test rig used for the research.

- Discrediting British science by ignoring warnings and publishing bad theory that defied the laws of conservation of energy and momentum.

- Misquoting the data presented in their own paper in order to enhance its plausibility.

- Misquoting Courtney's published research in in a manner that implied the EU Directive on soft pedestrian friendly bumpers could not be met by SALi Technology.

3 How the Formal Enquiry Panel dealt with the evidence

3.1 The Panel refused to examine Courtney’s evidence on the grounds that he had failed to follow the correct academic procedure.

In their Report, the Panel wrote,

“If Mr Courtney disagreed with the results, he should have pursued the accepted practice in the academic community of writing to the editor of the journal and presenting a rebuttal which, like the original paper, would be presented for peer review before being published.

The Panel did not uphold this allegation.”

[Gleeson, Duck et. al., Formal Enquiry Report, University of Manchester, January 2010.]

This statement is dishonest and suggests that Courtney was professionally incompetent. More seriously, it amounts to secondary fraud, because it misleads the EPSRC who funded the research.

3.2 This deception is easily discredited.

Courtney had followed accepted practice by writing to the editor of the journal who passed his rebuttal up the line to the Director of Publishing. The Publisher took legal advice on the matter and then advised Courtney to take his complaints directly to Manchester University.

All of this history was made clear to the Panel.

Most bizarrely of all, the evidence Courtney presented to the Panel took the form of a copy of his original letter to the journal. This is the Document D1 that you will see below.

4 How did the authors gat away with publishing bad science?

Bad science only ended up being published because the journal's editorial process was sloppy.

The annotated version of the paper presented below has been colour coded to help you spot the referees mistakes.

- Careless technical essay writing mistakes that should have been spotted by the referees are highlighted in yellow. Some are blatantly silly, others are trickier to spot.

- More serious mistakes, where the referees failed to recognise violations in the laws of conservation of energy and momentum have been highlighted in blue.

- The uncoloured annotations in red font relate to mistakes that could only be spotted by Courtney with his insiders knowledge of the research.

- The annotated paper is followed up by a more detailed discussion of the authors' errors. The same yellow and blue coding is used to highlight the errors that should have been spotted by the referees.

Document D1 begins

CHESHIRE INNOVATIONâ

Engineering Consultancy

17 Vale Road, Timperley, Altrincham, Cheshire, WA15 7TQ, UK

Tel/Fax +44 161 980 5191, Mobile: 07913561887

Web site www.cheshire-innovation.com

29th February 2008

Philip DiVietro, Managing Director, Publishing

ASME International,

Three Park Avenue

22S1 New York

NY 10016-5990.

Dear Mr DiVietro,

Objections to the publication of a paper in the Journal of Engineering Materials and Technology

Publication of the following paper is objected to

Characterization of the Core Properties of a Shock Absorbing Composite, G. Georgiades, S.O. Oyadiji, X.Q. Zhu, J. R. Wright, and J.T. Turner, Journal of Engineering Materials and Technology, ASME, October 2007, Vol. 129, pages 497-504

From the perspective of the innocent reader, this paper appears to present useful research findings relating to the complainant’s patented Shock Absorbing Liquid (SALi) TechnologyTM. However, as the only peer who has published journal papers on SALi Technology, the complainant is aware that the JEMT reader has been seriously misled.

Previous evidence sent to ASME International in the form of verifiable emails and copies of numerous documents on a CD ROM provide clear evidence that the deception of the JEMT reader has not happened by accident.

Prior research carried out by the complainant, Bill Courtney, and verified by researchers at several universities indicates that SALi Technology has the potential to save lives and protect impact accident victims from severe injuries.

The complainant will present verifiable evidence that JEMT readers have been tricked and that the good name of SALi Technology has been unfairly damaged.

Background

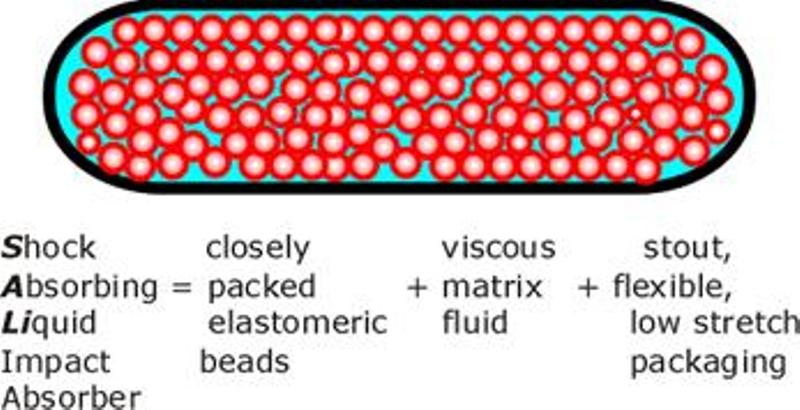

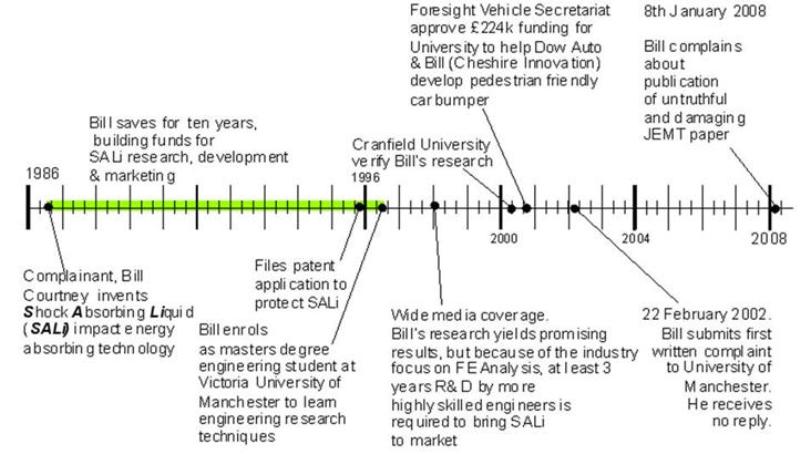

Bill Courtney invented SALi Technology in 1986.

His impact energy absorbing devices consist of flexible, high tensile stiffness bags filled with a blend of small, closely packed elastomeric beads with a viscous matrix fluid filling the void spaces between the beads.

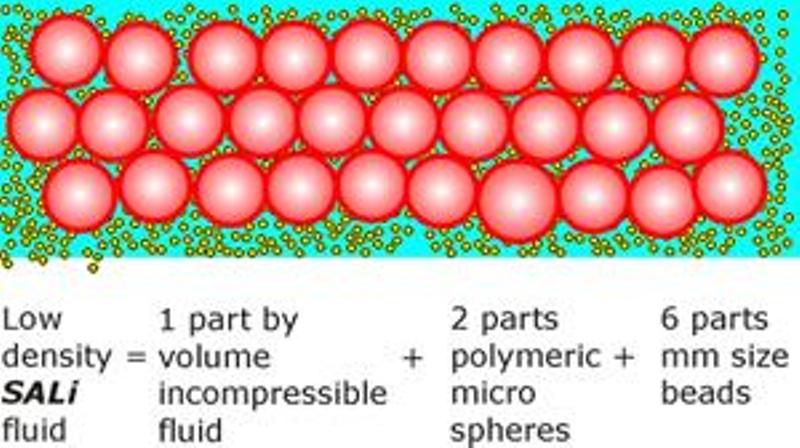

Figure 1. The basic SALi impact absorber concept

The weight of a SALi type impact absorber can be reduced and its impact energy absorbing efficiency improved by bulking out the matrix fluid using polymeric micro-spheres.

Figure 2. The relative size of the polymeric micro-spheres is exaggerated for illustrative purposes. Compared with the basic formulation, the micro-spheres increase the proportion of low density compressible material from 67% to 89%, but the total solid surface area increases by a factor of 20. This produces a corresponding increase in viscous damping.

The practical implication is that lightweight SALi devices also offer a significantly higher impact energy absorbing capacity.

For ten years, Bill lived economically, building up the financial reserves that would allow him to file international patent applications and work full time developing SALi Technology.

From 1996 onwards he worked with the Victoria University of Manchester, initially as a mature MPhil student, then as a Fellow of the University.

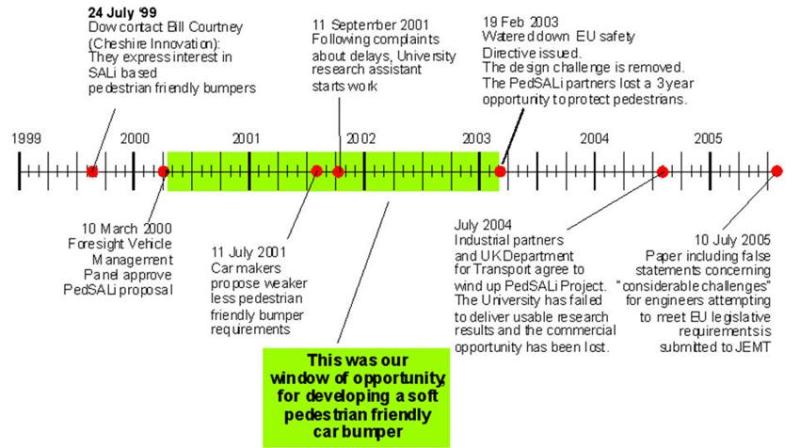

The JEMT paper is an outcome of the PedSALi project to meet historical European Union legislative requirements (now lapsed) relating to soft car bumpers, to protect pedestrians in motor vehicle accidents. The project partners were the Automotive Division of Dow Chemicals, Bill Courtney under his trade name of Cheshire Innovation and the Victoria University of Manchester.

The project aim was to design a bumper that was soft for pedestrian impacts but stiff for other types of low speed impacts such as collisions with street furniture.

Three years after the project was approved, the University had failed to deliver any usable research results to Dow, so the industrial partners agreed to wind up the project in June 2004. There were no other commercially viable solutions to the conflicting bumper stiffness requirements. Consequently, the legislation was watered down and pedestrians remain under an unnecessary threat of crippling injuries.

If the truth about the failure of the PedSALi project is exposed, future pedestrians will have another chance of SALi protection from crippling injuries. On the other hand, if an illusion that SALi Technology is flawed can be maintained, a small segment of academia will saved from embarrassment.

Figure 3. Twenty two years after Bill Courtney invented SALi Technology he is still struggling against attempts to destroy its good name.

The annotated copy of the paper below gives the ASME an overview of the objections.

This is followed by a detailed presentation of his objections to publication.

Annotated copy of

Characterization of the Core Properties of a Shock Absorbing Composite, G.

Georgiades, S.O. Oyadiji, X.Q. Zhu, J. R. Wright, and J.T. Turner,

Journal of Engineering Materials and Technology, ASME, October 2007, Vol. 129, pages 497-504

Courtney's annotations are added in red font.

The original document text is difficult to read, so the relevant sections have been retyped in a clearer font.

Page 497

Page 498

Page 499

Page500

Page 501

Page 502

Page 503

Page 504

Detailed presentation of the objections to publication

It is assumed that potential respondents have access to document AC2 and the Exhibits referred to in the text. Please contact This email address is being protected from spambots. You need JavaScript enabled to view it. if you require copies. These will be posted on a CD ROM.

1 Introduction

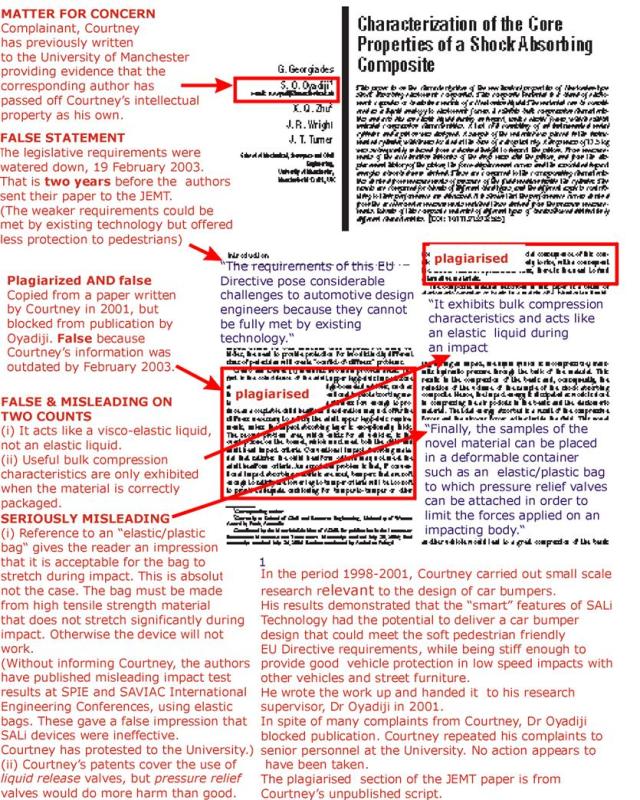

1.1 In the first paragraph the authors write,

“A new European legislation, which came into force in 2005, requires that the vehicle bumpers be more pedestrian friendly. The requirements of this EU Directive pose considerable challenges to automotive design engineers because they cannot be met by existing technology.”

(Underlined by the complainant.)

This is a seriously damaging half truth. The challenging problems could not be resolved so the legislative requirements were watered down 19 February 2003. That is, two years before the authors sent their paper to the JEMT.

There are no “considerable challenges” because the reduced levels of pedestrian protection can be met using existing technology. The existence of new motor vehicles on the roads of Europe is proof of this.

The following road safety pressure groups can verify that the legislation was watered down and that pedestrians remain at risk:

RoadPeace http://www.roadpeacelancashire.org/applogic/contactus/contactus.html

European Federation of Road Traffic Victims This email address is being protected from spambots. You need JavaScript enabled to view it.

Figure 4. The authors would have been aware that they were deceiving JEMT readers with their statement concerning “considerable challenges” to engineers.

Figure 4. The authors would have been aware that they were deceiving JEMT readers with their statement concerning “considerable challenges” to engineers.

Dow and the complainant (Bill Courtney trading as Cheshire Innovation) lost a business opportunity worth $90 million/year. (Exhibit 7 on the CD ROM) But the real losers may be pedestrians crippled by unnecessary crash injuries.

The EU is still hoping that the design problems can be solved and that soft pedestrian friendly bumpers will be mounted on all new vehicles sold after 2012.

In principle, the complainants’ design could solve the problem, but the damaging mistruths presented in the JEMT paper will make it very difficult to attract research funding.

1.2 The second paragraph of the Introduction is plagiarised from a script by the complainant, Courtney. The script originally read,

“Clemo identifies two main problem areas. The first is the coincidence of the adult upper leg and pelvis impact zone and the child head impact zone on high-bonneted vehicles such as the 4 x 4 and utility classes. If conventional impact absorbing materials are used, a bonnet which has a stiffness low enough to produce an acceptable child headform deceleration, may not offer the stiffness necessary to satisfy the adult upper leg and pelvis requirements, unless the impact absorbing layer is exceptionally thick. The second problem area, which exists for all vehicles, is the overlap zone on the bonnet which must meet both the child and adult head impact criteria. The child headform, used for tests, has a mass of 2.5 kg and a maximum kinetic energy on impact of 154 J. The adult headform has a mass of 4.8 kg and a maximum kinetic energy on impact of 295 J. Conventional impact absorbing material which satisfies the child headform criteria, may not meet the adult headform criteria. An associated problem is that, if conventional impact absorbing materials are used, bumpers which are soft enough to satisfy the lower leg to bumper criteria will be too soft to provide adequate cushioning for bumper-to-bumper impacts. The commercial consequence of this bumper design conflict is that, vehicle repair costs are likely to rise, with a consequent increase in insurance premiums.

The plagiarised document is a draft journal paper suppressed by Dr Oyadiji. The suppression issue is discussed as “11th challenge to the right of the University to pursue CI for debt recovery”, document AC2, page 21.

The JEMT reader has been misled by the plagiarised text. Courtney’s words were true when he wrote them in 2001 but were out of date by the time the paper was sent to the JEMT in July 2005. It is particularly frustrating to the complainant that his own words have been stolen and distorted for use against him.

1.3 In the second paragraph, second column, first page, the authors describe a composite material that “exhibits bulk compression characteristics”.

This statement is misleading, particularly if read in conjunction with other false statements concerning SALi packaging made elsewhere in the paper.

The material only exhibits these characteristics if it is packed in a stout, high tensile strength bag. The misleading statement is unlikely to be a typing error because the authors have been hoodwinking the international research community on the packaging issue for the last three years. Please see document AC2, Appendix 1, page 26 for details.

1.4 In the third line from the bottom of the first page, the authors refer to the use of “an elastic/plastic bag”. (Complainants underlining)

This is an additional deception of the JEMT reader which reinforces the deception in 1.3 above.

A bag that stretches would perform hopelessly under impact. The bag would expand in preference the enclosed materials being significantly compressed. This potential design flaw has been known to the corresponding author for the past twelve years.

1.5 The authors also suggest that a pressure release valve would be useful. This is the exact opposite of the truth. Reducing the pressure would reduce the effectiveness of the SALi, in a similar manner to using an elastic bag. The authors are aware that the complainant, Courtney has proposed SALi devises that include incompressible fluid transfer valves, but these serve an entirely different function to a pressure release valve.

.

1.6 In the last sentence of the first page the authors appear to offer an explanation of how the bumper behaves differently for bumper-to-bumper and pedestrian impacts. This is an illogical explanation. The clear thinking JEMT reader would be forgiven for concluding that the person who invented this type of bumper (the complainant) was talking nonsense. For a correct explanation of how the bumper was intended to work please visit the PedSALi page on the Cheshire Innovation web site, www.cheshire-innovation.com

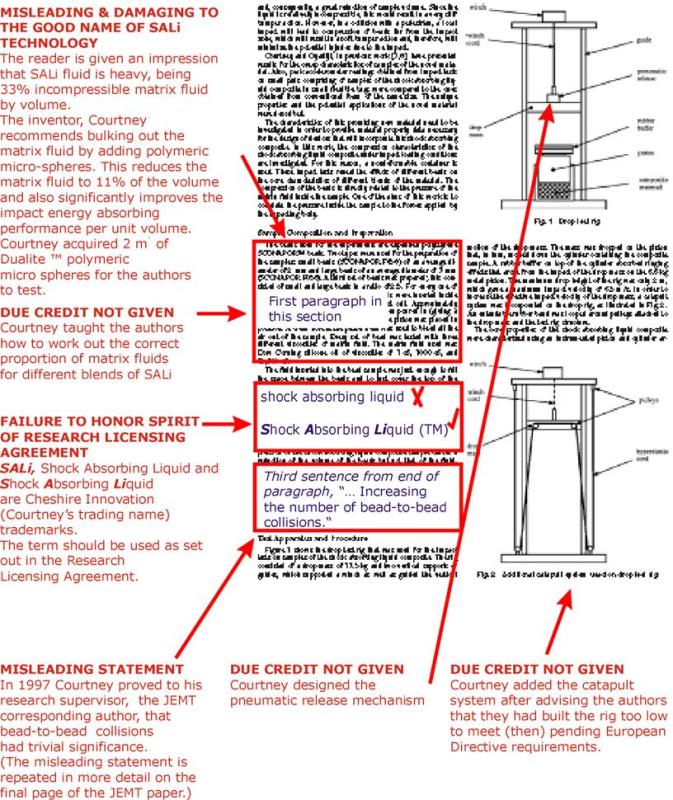

2 Sample composition and preparation

2.1 The authors’ state that 170 ml of matrix fluid was added to the beads. But they fail to state that this quantity was only known to be correct because of a series of experiments carried out by the complainant, Courtney, as one of his contributions to the PedSALi Project. Please see Section 2.1 of the attached document, “CI Report for Fourth PedSALi Meeting” for evidence that Courtney carried out the background experiments.

Courtney’s contribution should have been acknowledged.

To assist JEMT readers, it would also have been sensible to explain briefly how the optimum amount of matrix fluid was determined. This information is provided on the SALi Project Advice page of the Cheshire Innovation web site. www.cheshire-innovation.com

2.2 Weight is a key consideration in designing most types of impact energy absorber, including car bumpers. The authors’ state that bead to liquid volume ratios of three to one were investigated. In the absence of any additional information the JEMT reader would reasonably conclude that the proposed bumper would be very heavy because it was one third filled with liquid. In fact this was never the intention. Please see Section 2.2 of the attached document, “CI Report for Fourth PedSALi Meeting” for details of methods for reducing bumper weight. Also, see Figure 2 above.Under the UK Freedom of Information Act the complainant has obtained a copy of the final report on the University PedSALi research to the funding body, the Engineering and Physical Science Research Council. On page five of the report (copy available on request) the authors claim that in March 2004 Dow Automotive held a review following which they rejected the PedSALi design on weight grounds. This claim is false, but is consistent with the implied heavy weight message in the JEMT paper. Please see Exhibit 12 on the CD ROM for the real reasons why the PedSALi Project was wound up before a prototype bumper was tested.

2.3 The authors carried out their research under licence from Cheshire Innovation. (The complainants trading name.) Throughout the paper, the authors ignore the complainants’ intellectual property rights by referring to a “shock absorbing liquid”.

Shock Absorbing Liquid and Shock Absorbing Liquid are acknowledged as a Cheshire Innovation Trade Mark in Schedule 1.4 of the Licensing Agreement (reproduced as Exhibit 2 on the CD ROM) This Schedule of the Agreement should have been respected by the Authors. Capitals should have been used for the first letter of each word, followed, on the first occasion by TM thus:

Shock Absorbing Liquid TM

Or,

Shock Absorbing Liquid ™

3 Test Apparatus and Procedure

3.1 Re: Figure 2 captioned, “Additional catapult system used on the drop test rig”The corresponding author instructed Dr Zhu to build the drop impact rig to a lower drop height than agreed with Dow and Cheshire Innovation. This made impact tests to EU Directive standards impossible.

(CD ROM, Exhibit 19, page 4, final diary entry)

By the time the flawed design was openly discussed it was a fait accompli because expensive components had been purchased and cut to size. The authors credit themselves with solving this problem using a catapult system.

However, Section 2.5 of the attached document, “CI Report for Fourth PedSALi Meeting” shows that the complainant solved the problem.

He proposed and designed the catapult, sourced the materials and with technician help, constructed it. He also led the design of the novel pneumatic drop mass release mechanism referred to in the paper. These contributions were essential to the project, but are not acknowledged in the JEMT paper.

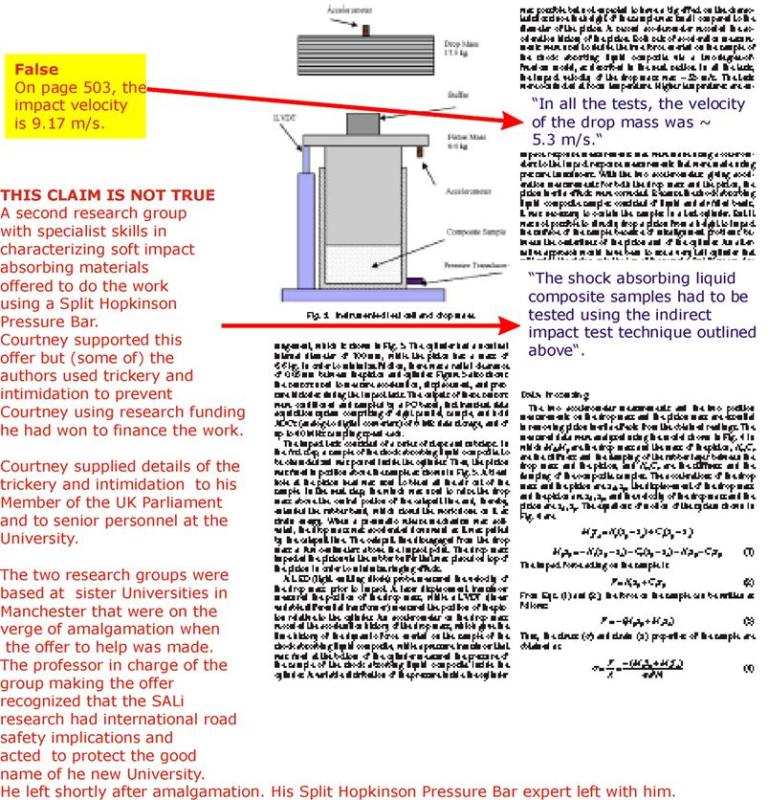

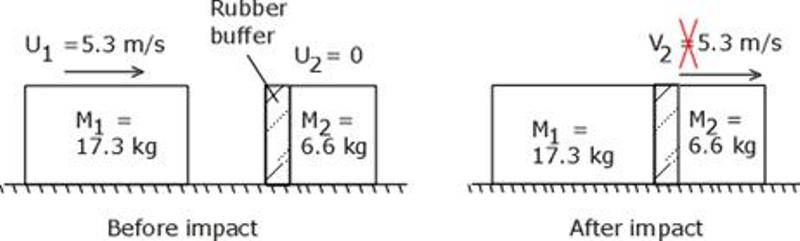

3.2 When correctly packaged, SALi devices mimic impact absorbers filled with a visco-elastic fluid. Viscous damping is a function of strain rate. So strictly speaking, the strain rate at each point on a core characteristic curve should be known. At the very least, the impact velocity should be known. In this section of their paper, the authors quote an impact velocity of 5.3 m/s. However the following notes will explain why this value is wrong.Towards the bottom of the first column of the third page, the authors write, “An accelerometer on the drop mass recorded the acceleration history of the drop mass, which gave the time history of the dynamic force on the sample of shock absorbing composite, …”

This statement cannot be true because it flouts the basic laws of physics that govern impacts.

The drop mass is not rigidly coupled to the piston and the piston has a finite mass, so the dynamic forces on them are different.

Thanks to the rubber buffer and the elastic component of the SALi, the drop mass bounces off the piston during the time history.

The bouncing was clearly visible to the naked eye.

Figure 3 in the paper indicates that the 17.3 kg drop mass collides with a thick rubber buffer resting on top of a 6.6 kg piston.

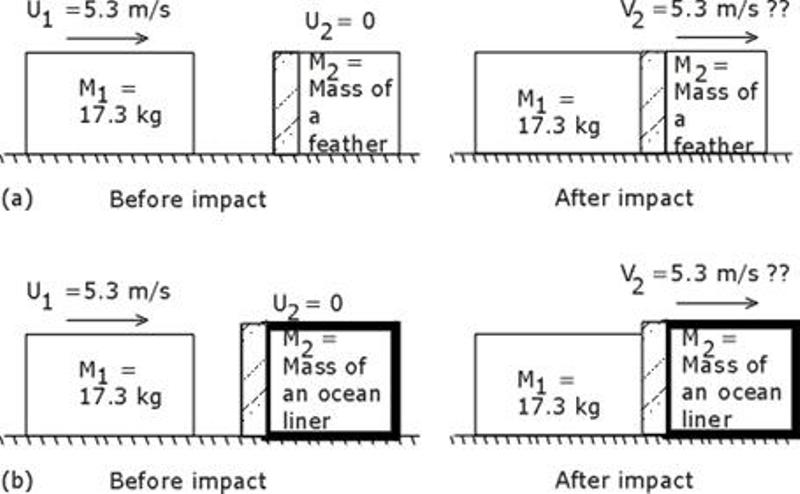

To calculate the dynamic force on the sample, the Law of Conservation of Momentum and the energy absorbing properties of the rubber buffer must be taken into account. Figure 5. The authors have failed to grasp the basic laws of physics governing impacts. Velocity changes occur on impact.

Figure 5. The authors have failed to grasp the basic laws of physics governing impacts. Velocity changes occur on impact.

By using the Law of Conservation of Linear Momentum and the kinetic energy formula, it can be shown that if by some fluke the rubber buffer absorbs precisely 24% of the pre-impact energy of the 17.3 kg mass, then the piston will move forward with the same velocity. But, this fluke could only hold true for one impact velocity because of the visco-elastic nature of rubber.The worked example in Figure 7 below shows that the possible error in the authors’ velocity claims could be up to 40%, for a perfectly elastic impact.The complainants’ research diary records that he was warning the corresponding author of test cell deign flaws as early as 27th March 1997. (Exhibit 19 on CD ROM, page 3.)

The complainant tried many different approaches over the years to persuade his University colleagues to take his criticisms seriously. For example, he constructed a strong fabric test cell that eliminated the heavy piston and the need for a rubber buffer. This cell was used in low energy impact tests. It produced distinctly different results to the cell illustrated in Figure 3 of the paper. The fabric cell is referred to in Section 2.3 of the attached document, “CI Report for Fourth PedSALi Meeting”

3.3 In the final sentence of this section the authors write, “The shock absorbing liquid composite samples had to be tested using the indirect impact test technique outlined above.

This statement is false. During the course of the PedSALi Project an opportunity to carry out valid tests using a polycarbonate Split Hopkinson Pressure Bar became available. Unfortunately, this opportunity was blocked by a combination of intimidation and trickery.

See document AC2, page 9, 4th Challenge for details.

4 Data Processing

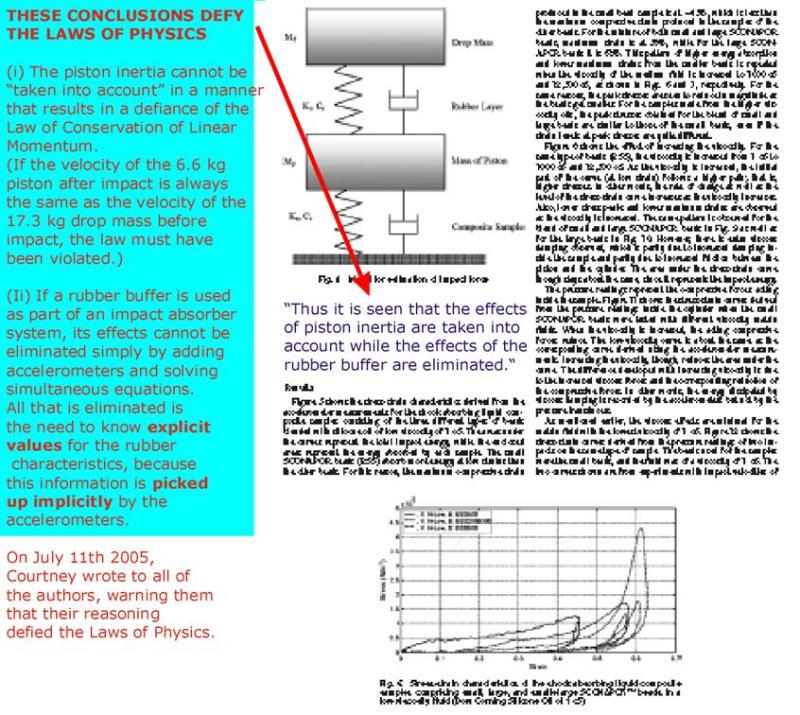

4.1 The authors present some algebra at the end of which they conclude, “Thus it is seen that the effects of the piston are taken into account while the effects of the rubber buffer are eliminated.” This statement is incorrect on both counts.

(i) Algebra and accelerometers cannot be used to defy the laws of physics. No amount of data processing can change the velocity of the piston to make it identical to the impact velocity of the drop mass on the rubber buffer. This is discussed in 3.2 above.

(ii) The effects of the rubber buffer are not eliminated. All that has been eliminated is the need to know explicit values for the elastic and viscous damping characteristics of the rubber, because the information is picked up indirectly in the accelerometer readings.

If the authors’ arguments were correct it would lead to some bizarre consequences. Simply by adding accelerometers and solving a pair of equations, it would make no difference to the impact conditions, whether the layer of rubber was one molecule thin, or two bricks thick.

The authors make the same mistake as many elementary algebra students when making a real life extrapolation of their maths. They assume that by eliminating an unknown variable from a pair of simultaneous equations, they have eliminated its real life effect.

The University colleagues were warned on several occasions that their deductions were illogical. To summarise, the authors’ reasoning implied that identical characteristics would be produced for a given drop mass velocity, irrespective of the thickness of the rubber buffer or piston mass.

4.2 This muddled thinking predicts some interesting effects. We will consider two extremes; a piston having a similar mass to a feather, then one as massive as an ocean liner. Figure 6. If the authors’ scientific reasoning and understanding of algebra had been correct, the consequences would have been bizarre.

Figure 6. If the authors’ scientific reasoning and understanding of algebra had been correct, the consequences would have been bizarre.

Irrespective of whether the piston had the mass of a feather or an ocean liner, the impact velocity of the piston on the sample would remain stable at 5.3 m/s. The basic laws of physics would have to be re-written.

The authors have got it wrong. In order to demonstrate this, the complainant requested that they measure the piston velocity directly to see if it really was 5.3 m/s. His request was ignored.

Note for web page readers.

Bill Courtney warned the authors on several occasions that they were in danger of looking very foolish by publishing work that “defied” the laws of physics. To see a specific warning that was also copied to the EPSRC and presented to the Panel as Exhibit 10, please click.

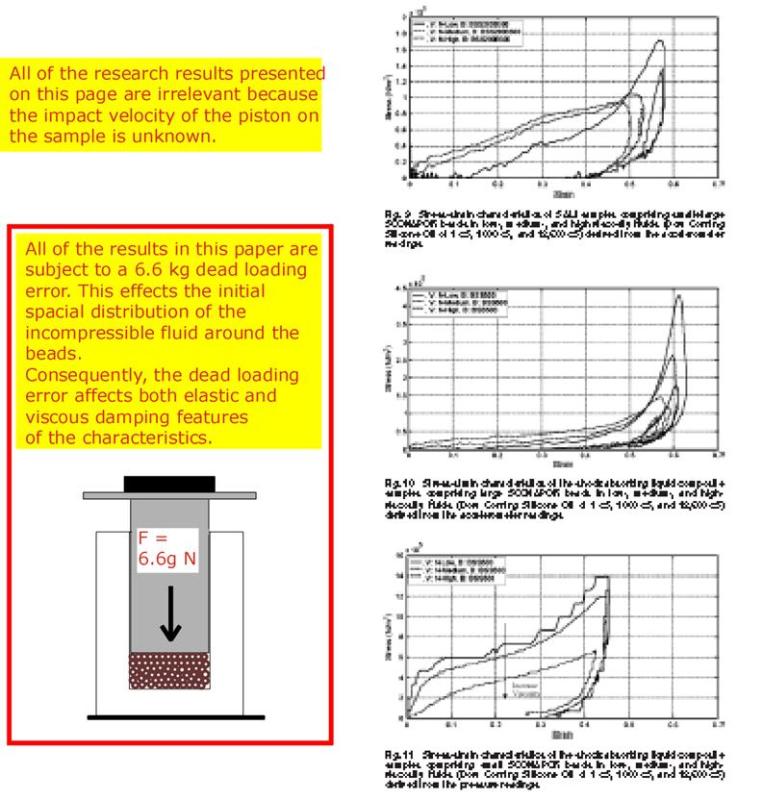

4.3 The authors fail to mention the pre-loading error caused by the weight of the 6.6 kg piston. This has three components.

(i) The total volume of SALi being tested is less than the stated 500 ml, because of the pre-compression.

(ii) The ratio of compressible bead volume to incompressible matrix fluid is reduced.

(iii) The beads are no longer in close contact at the first moment of impact. This reduces the initial contribution of viscous damping.

The authors were warned about the pre-loading error.

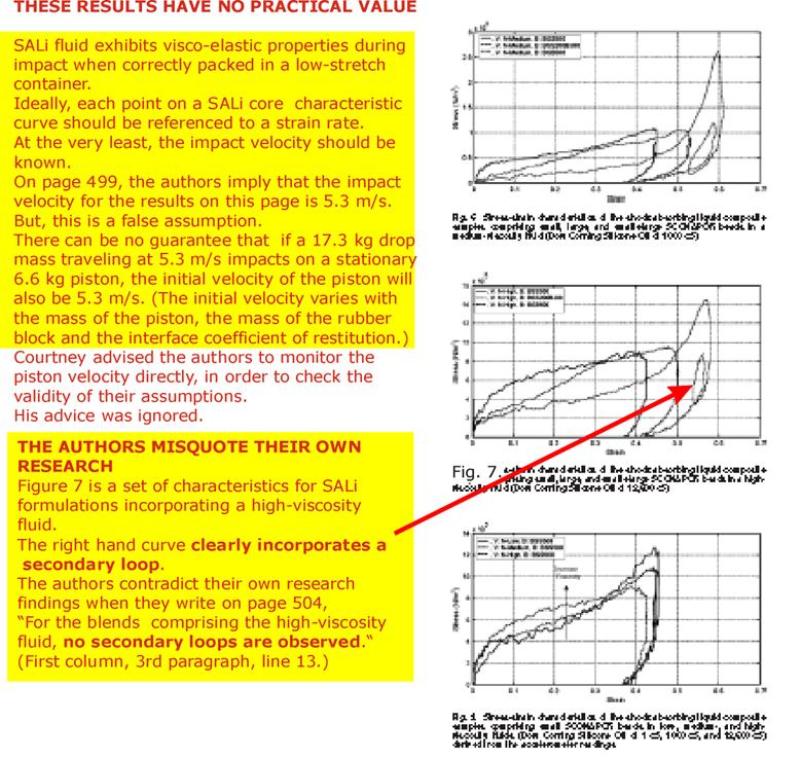

5 Results

The debate over valid velocity measurements was a constant source of friction during the years of the PedSALi Project. The complainant argued that accurate knowledge of velocities and strain rates was crucial to any investigation of visco-elastic phenomenon.

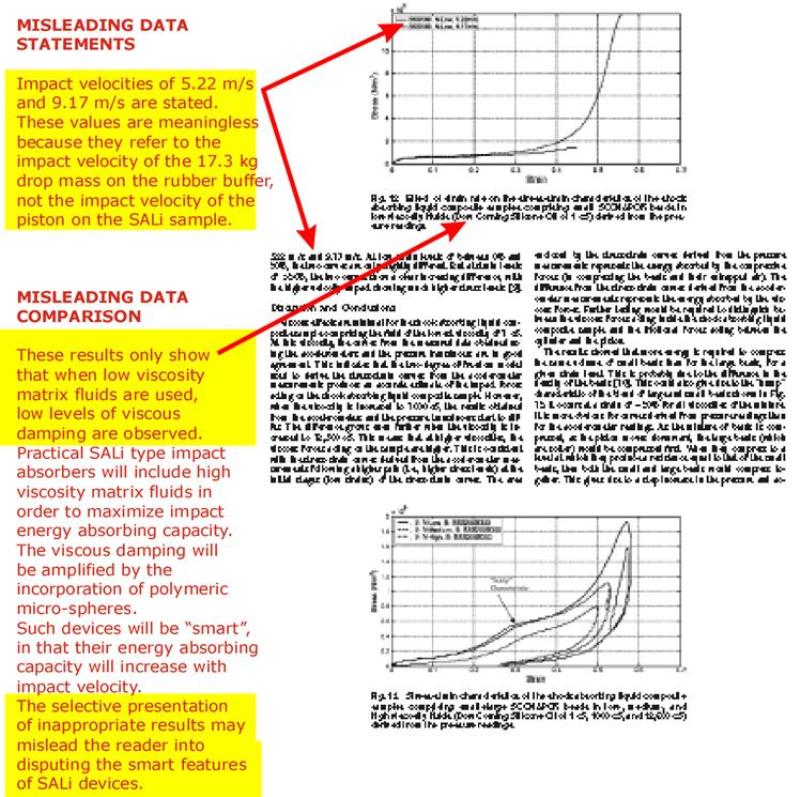

Figure 12 in the paper appears to refute this, so it requires closer examination. The figure shows similar stress-strain characteristics for “impact velocities” of 5.22 m/s and 9.17 m/s. But this is deceptive because the experiments were carried out using a watery thin, 1 cS matrix fluid.

The only thing these results tell the reader is that if a low viscosity fluid is used, then low levels of viscous damping are detected.

In order to give the reader a balanced understanding, comparable results using high viscosity matrix fluids should also have been presented. Such experiments were carried out as part of the PedSALi research.

In terms of engineering applications of SALi Technology, the reader has been misled and the credibility of the PedSALi bumper design undermined. The PedSALi car bumper design will only offer “smart” impact energy absorbing properties if the SALi responses to high and low strain rates is significantly different. Unpublished results show that this is possible if high viscosity matrix fluids are used.

Smart bumpers are discussed on the PedSALi web page at www.cheshire-innovation.com.

6 Discussion and Conclusions

6.1 At the end of the first paragraph the authors write, “Further testing would be required to distinguish between the viscous forces acting inside the shock absorbing liquid composite sample and the frictional forces acting between the piston and cylinder.”There is a prior stage that should have been explored with JEMT readers. Before attempting to distinguish between different types of damping, the total damping effect needs to be identified and separated from the work done in compressing the beads. In order to do this, the results of quasi-static compression experiments should have been presented.

However, there was a big question mark over the quasi-static work carried out during the project. The Internationally recognised piece of equipment for quasi-static compression tests is the Instron Machine. Unfortunately, the University Instron Machine was broken, so primitive experiments involving hand loading of weights had to be carried out. The data output from the position sensors was extremely noisy and unsuitable for analysis. The complainant negotiated an opportunity for a Instron Machine at another university (UMIST) to be used, but this was rejected by the authors.

See document AC2, page 35, Box 8.

6.2 The initial practical work for the PedSALi Project was an electron microscope investigation of the internal structure of the Dow Sconapor beads. This early work reinforces the need for presenting JEMT readers with quasi-static compression test results.

Courtney and Zhu cooled beads in liquid nitrogen, sliced them with a sharp blade, and then examined the bead cross sections using an electron microscope.

They noted that the beads have a complex stratified structure, with the cell size dropping by at least an order of magnitude towards the outer surface. As cell size dropped, cell wall thickness increased. For small beads, the thicker walled outer cell layers occupied a greater fraction of he total volume.

Implications for understanding the core characteristics of SALi fluid:

The stratified nature of the beads suggests that the compressive characteristics of large and small beds are qualitatively different. In turn, these are likely to be significantly different to the compressive characteristics of blocks of foam, steam moulded from Sconapor beads.

These differences needed to be understood. Good quality quasi-static tests using an Instron Machine should have been carried out and written up before moving on to the dynamic impact tests.

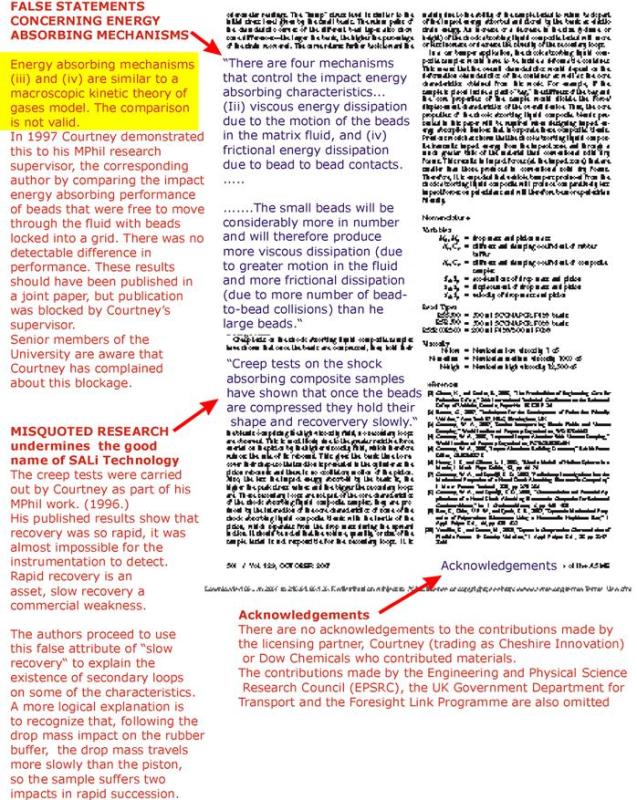

6.3 In the second paragraph, final page, the authors make (apparently) factual statements concerning four mechanisms that control impact energy absorption.

This is a serious deception. For the last ten years it has been known that mechanisms (iii) and (iv) are invalid. The authors imply that during impact the movement of the elastomeric beads is analogous to a macroscopic version of the kinetic theory of gases, with the beads suffering viscous drag as they move through the matrix fluid and also losing energy in head-to-head impacts.

The experimental evidence proves these explanations are false:

In 1997 the complainant, Courtney provided his research supervisor Dr Oyadiji with clear evidence that

(a) damping of translational movement of beads through the matrix fluid and

(b) head-to-head collisions were not significant impact energy absorbing mechanisms.

He did this by comparing the impact energy absorbing performance of free moving and static bead formulations of SALi.

Expanded polystyrene beads were used for the free moving versions of SALi and sheets of bubble packing (AirCap) for the static versions. The impact energy absorbing performances of both versions were comparable, with the main difference being attributable to the viscosity of the matrix fluid used. The results were published in Courtney’s MPhil thesis. [Courtney, W. A., Preliminary Investigations into the Mechanical Properties and Potential Applications of a Novel Shock Absorbing Liquid, Manchester School of Engineering, University of Manchester (1998)]

The results should also have been published in a journal paper by Courtney and Oyadiji, but as mentioned in Section 1.2 above; its publication has been blocked by Dr Oyadiji. The relevant research results are attached as “Extracts unpublished Auto Journal paper”. JEMT readers have been misled by an implausible explanation that was discredited ten years ago. This is a serious deception because any JEMT reader attempting to mathematically model the dynamic action of Shock Absorbing Liquid could end up wasting considerable time and being made to look professionally foolish.

Please see AC2, numbered sections 1 and 2, page 34 for an example of when this almost happened on a previous occasion.

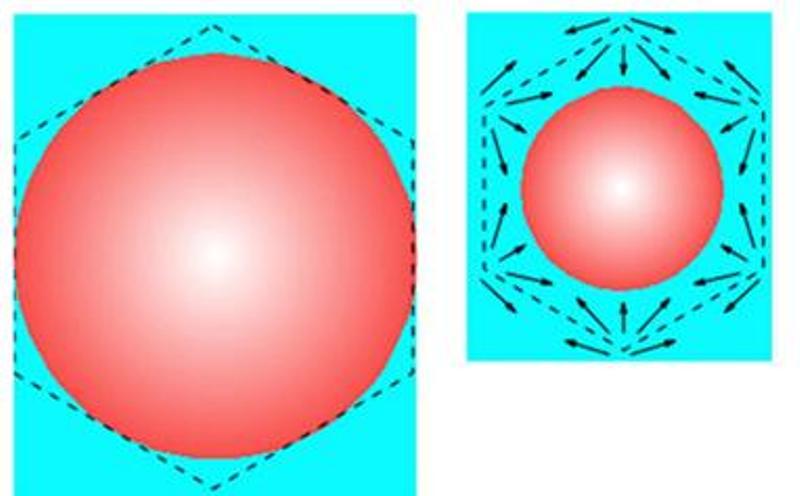

Figure 7. Any serious attempt to mathematically model SALi devices during impact will probably need to consider unit cells of the composite material. This pair of diagrams shows a simple two dimensional array of cells.

Figure 8. During impact, the size of a unit cell of SALi decreases, with the matrix fluid occupying a greater fraction of the cell. The arrows indicate approximate directions of fluid movement. Shearing between layers of the moving fluid produces viscous damping.

These diagrams are based on observations of SALi samples during compression, using a transparent Perspex piston and cylinder packaging. The experiment was done at another university and the sample was compressed using an Instron Machine.

6.4 In the same paragraph the authors write, “For a shock absorbing liquid composite sample of the optimum ratio of beads to matrix fluid, the beads are totally covered by the fluid and are initially in contact.”

If good experimental design had been used, this statement would have been correct. It is not true for the test cell described on the JEMT paper because of the 6.6 kg dead weight pre-loading error.

6.5 Towards the end of the same paragraph the authors write, “Thus for the same volumes of the small and large bead shock absorbing liquid composite samples, the small beads will be considerably more in number and will therefore produce more viscous dissipation (due to greater motion in the fluid) and more frictional dissipation (due to more number of bead-to-bead collisions) than the large beads. These deductions are borne out from the results, which show that the small beads absorb (or dissipate) more of the impact energy than the large beads.”These statements echo the untruthful statements in 6.2 above. The complainant comments: Amore realistic explanation for the greater impact energy absorbing capacity of small bead SALi is that:

(a) the small beads are stiffer than the large one,

and

(b) generate more viscous damping because of their larger surface area per unit volume of SALi.(a) Evidence for greater stiffness:

The stiffness hypothesis is supported by simple experiments carried out by the complainant twenty two years ago in 1986 and later work with Zhu in 2001.

(b) Evidence for greater surface area causing greater viscous damping.

In 1986 the complainant carried out very basic mathematical modelling of SALi. He demonstrated that for two bead/bead sizes having mean radii R1 and R2, the total surface areas per unit volume of SALi composite material were in the ratio R2/R1 So, for example, if the mean radius drops from 2.5 mm to 2.0 mm, the total solid surface area per unit of SALi increases by 25%.

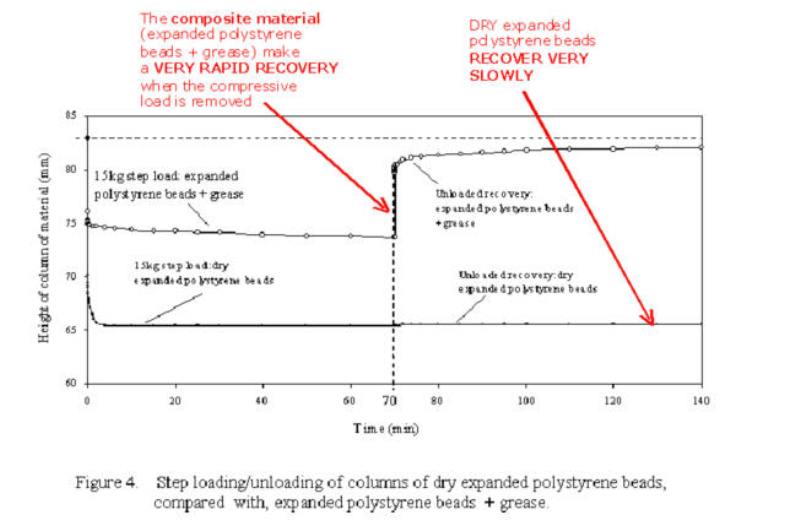

6.6 The third paragraph on the final page begins, “Creep tests on the shock absorbing liquid composite samples have shown that once the beads are compressed, they hold their shape and recover very slowly”

This is a very damaging falsification of the truth that unfairly tarnishes the good name of SALi Technology. Creep tests have shown that DRY samples of the beads are very slow to recover but when the matrix fluid is added, the composite mixture makes a very rapidrecovery, even after being held in the compressed state for seventy minutes. These comparative results have been published in two journal papers. Please se attached document, “Creep exposed” for a relevant extract from the following paper,

Courtney, W.A. and Oyadiji, S.O. Preliminary investigations into the mechanical properties of a novel shock absorbing elastomeric composite, Journal of Materials Processing Technology, 119 (2001) 379-386.

A copy of the second paper was emailed to Philip DiVietro, 6th February 2008.

It is difficult to avoid the conclusion that the JEMT reader has been intentionally misled by the authors..

6.7 The explanation in the third paragraph on the final page also violates the law of conservation of energy.

The first three sentences of the third paragraph on the final page read, “Creep tests on the shock absorbing liquid composite samples have shown that once the beads are compressed, they hold their shape and recover very slowly. Consequently, in the impact tests, after maximum strain is attained and the piston starts to rebound, suction is created in the cylinder because the beads have not yet had time to recover heir shape. This causes a resistive force that opposes the upward movement of the piston and results in the oscillatory movement of the piston.”

In order for the piston to rebound against the force of gravity it must receive energy. The impact energy density in a compressed elastic material = ½ x maximum stress x maximum strain. (To a first approximation.) The composite material is far more compressible than the steel piston, so the vast bulk of the recoverable impact energy is stored in the compressed composite material.

The material has to recover very quickly to drive the piston back up the cylinder.

once the beads are compressed, they hold their shape and recover very slowly" was true, there would be no source of energy available to drive the rebound.

This muddled thinking was combined with research fraud.

Telling this lie "absolves" the authors of any responsibility for soft SALi based bumpers not being fitted to cars.

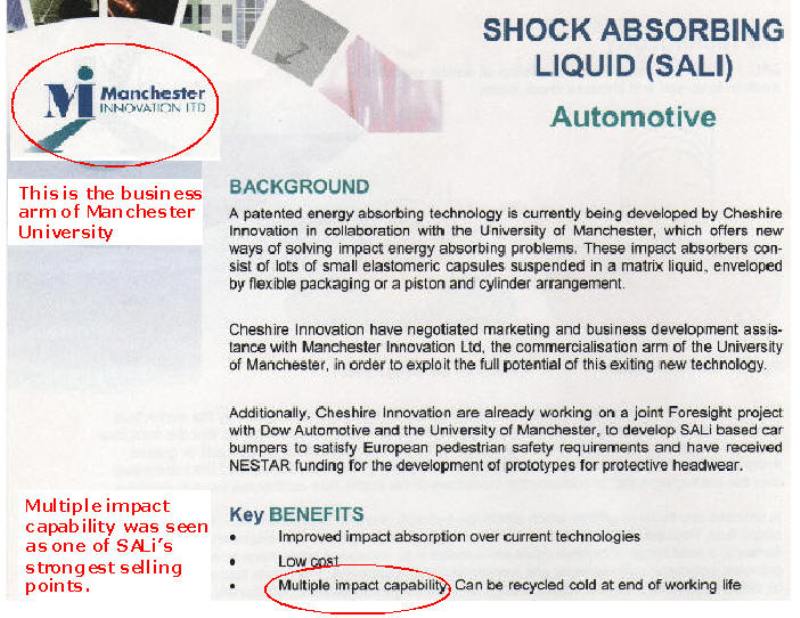

(ii) Secondary evidence of rapid recovery comes from the business arm of Manchester University, who were actively engaged in selling the rapid recovery feature of SALi based impact absorbers.

Additional information for web page readers

(i) The following extract from the authors Reference 8 (annotated in red for web page readers) provides

verifiable proof that they wilfully deceived JEMT readers by claiming that the composite material had poor

recovery properties.

This graph shows the results of a creep test, as referred to by the authors.

[Reference 8, Courtney W A and Oyadiji S O (2000). Characteristics and potential applications of a novel shock absorbing elastomeric composite for enhanced crashworthiness. International Journal of Crashworthiness 5:4 (2000) 469-490.]

=============================================================

(ii) The following extract from a promotional leaflet demonstrates that the business arm of Manchester University

was aware of the real facts about SALi's rapid impact recovery properties.

(Courtney has annotated the extract in red font.)

(iii) In spite of a recommendation by Courtney, the Formal Enquiry Panel did not interview any of the members of the business arm of the University, who knew the truth about SALi's rapid recovery properties.

6.8 The authors refusal to heed early warnings about their violations of the laws of physics

At a meeting with PedSALi University colleagues, 16th October 2001, the complainant gave a short presentation on the physics of impacts. His explanation predicted that secondary loops would be observed as a consequence of the flaws in the experimental design.

He explained that if a 17.3 kg drop mass travelling at 5.3 m/s impacts on a stationary 6.6 kg mass then a transfer of momentum occurs. To calculate the velocities after impact, the coefficient of restitution of the interface needs to be known. Several different scenarios were worked through. The diagram below summarises the results for a coefficient of restitution of one. (That is, a perfectly elastic collision.) Figure 9. This pair of diagrams is only an approximation of what actually happens because the compression and then expansion of the thick rubber buffer adds complexity. Nevertheless, it can be seem that the velocity of the piston during the early stages of impact is substantially higher than that of the following drop mass. The piston does work compressing the sample and comes to a halt. If viscous damping is low and the beads are resilient, the piston will be just stating to move back up the cylinder when the drop mass catches up with it, delivering a secondary impact. This produces the secondary. Stress-strain loop. This explanation can be tested by experiment.The complainant urged his University colleagues to check his predictions by monitoring both piston and drop mass velocity changes during impact. If necessary, a high speed camera could have been used to settle the dispute beyond doubt.

Figure 9. This pair of diagrams is only an approximation of what actually happens because the compression and then expansion of the thick rubber buffer adds complexity. Nevertheless, it can be seem that the velocity of the piston during the early stages of impact is substantially higher than that of the following drop mass. The piston does work compressing the sample and comes to a halt. If viscous damping is low and the beads are resilient, the piston will be just stating to move back up the cylinder when the drop mass catches up with it, delivering a secondary impact. This produces the secondary. Stress-strain loop. This explanation can be tested by experiment.The complainant urged his University colleagues to check his predictions by monitoring both piston and drop mass velocity changes during impact. If necessary, a high speed camera could have been used to settle the dispute beyond doubt.

Comment for web page readers

This invitation by a mere "Mr" to his "Dr" colleagues was declined. He was "reassured" that he had failed to grasp the physics of impacts.

Saving professional embarrassment by refusing to test a prediction was unethical, because human lives turned on the outcome of the PedSALi research.

7 Acknowledgements

There are no acknowledgements to the contributions made by the licensing partner (the complainant) or Dow Chemicals who contributed materials.

The contributions made by the Engineering and Physical Science Research Council (EPSRC), the UK Government Department for Transport and the Foresight Link Programme are also omitted.

The reader is left with the impression that the JEMT paper was a unilateral unsupported project carried out by the authors. The reader would have no choice but to contact the corresponding author, either for clarification, or for proposing future collaborative work. This is deeply worrying to the complainant in the light of two previous experiences where the corresponding author appears to have passed off SALi intellectual property as his own.

For details of the first incident, please see document AC2, page 17, 9th challenge.

Details of the second incident are available on request.

Was publication justified?

The attached document titled “The case for publication” appears to provide a plausible legal justification for publication of the JEMT paper. Point number 2 states, “Dr Oyadiji asserts that Mr Courtney was given copies of drafts but had not objected to publication within a prescribed time.”In response, a very detailed letter including a copy of document AC2 and all the Exhibits was sent to .Professor Rod Coombs; 17th March 2007. (Royal Mail, First Class, Signed For Delivery)

This provided clear evidence that Dr Oyadiji’s assertion was false.

No reply was received.

The document titled “Breach of Agreement Evidence” posted to ASME International on a CD ROM, 21st January 2008, provides further evidence that Dr Oyadiji’s assertion was false.

Point number 3 in the letter from .Professor Coombs refers to a paper being accepted for publication. For the best part of the year 2007 the complainant was fooled into thinking that this was the ghost paper referred to in email 3 of 3 to Philip DiVietro, 23rd January 2008.

However, it is now clear that the ghost paper was never submitted for publication and that the paper referred to is the JEMT paper.

The ghost paper looked suspicious as early as March 2007. A second letter was written to .Professor Rod Coombs, 27th March 2007, raising doubts about the ghost paper.

(Royal Mail, First Class, Signed For Delivery)

No reply was received.Prior to the date of the Professor Coombs letter the complainant had supplied two successive Vice Chancellors of the University of Manchester and various other senior University personnel with detailed evidence of unprofessional conduct by (some of) the authors.On the second page of his letter, Professor Coombs presents the Head of the School of Engineering’s conclusion that, “It would seem that Dr Oyadiji was motivated strongly by a desire to publish in order to obtain a good report from EPSRC …”

The complainant argues that a desire to please the funding body does not legitimise the publication of false knowledge. If a university is prepared to turn a blind eye to unethical professional conduct in order to secure research funding, then the integrity of all of us involved in the scientific process is undermined.

The complainant has subsequently raised these issues with the University Registrar. His response (29 June 2007) was low key, concluding that, “The University has been satisfied that it has behaved properly and complied with its legal and other obligations.”

Summary of implications for JEMT readers

(i) Readers may be discouraged from carrying out their own research into SALi Technology because of the misleading impression presented by the authors, that SALi devices are heavy and make a poor recovery after impact.

(ii) They may also be put off by the false and illogical explanation of how a car bumper incorporating SALi Technology would be soft for pedestrian impacts, but stiff for other types of impact.

(iii) If they make a prototype device, it is unlikely to work effectively because of the authors misleading statement that the packaging should be either elastic or plastic.

(iv) If they attempt to use the characteristic data presented in the paper to carry out finite element type computer modelling, their results will be at complete variance with reality, because the impact velocity experienced by the test sample is different to the impact velocity of the drop mass.

(v) If they attempt to carry out their own characteristics experiments using the test cell and other apparatus as described in the paper, they will obtain invalid data because of the zero error and the invalid impact velocity value.

(vi) If they attempt to produce a kinetic model in line with the authors’ explanation of how the elastomeric beads move under impact, they will be wasting their time and exposing themselves to professional ridicule, because the kinetic explanation is flawed.

(vii) If they seek further clarification on SALi Technology or pedestrian friendly bumpers, their access to the most experienced peer is blocked because information about the licensee has been withheld.

(viii) On a more positive note, the complainant and licensee Bill Courtney emphasises that he is willing to advise JEMT readers and sign licensing agreements that will allow them to carry out research into SALi Technology. Such agreements would give readers access to improved versions of SALi, currently in the private domain.

The complainant looks forward to the day when valid papers on SALi Technology are published in the Journal of Engineering Materials and Technology.

The complainant hopes that JEMT readers will relish the engineering challenges and take up his offer.

Recommendation

In the course of misleading JEMT readers, the authors have unfairly discredited twenty two years of work and investment by the complainant.

SALi Technology has the potential to save lives and minimise injuries in violent impact accidents.

The dissemination of false knowledge about SALi Technology, simply to please a funding body, is professionally unethical and fundamentally immoral.

The following paper should be withdrawn before it causes further unnecessary damage:

Characterization of the Core Properties of a Shock Absorbing Composite, G. Georgiades, S.O. Oyadiji, X.Q. Zhu, J. R. Wright, and J.T. Turner, Journal of Engineering Materials and Technology, ASME, October 2007, Vol. 129, pages 497-504

Special Pleading

In the interests of justice, two of the authors, the research assistants, Drs Zhu and Georgiades should be treated as innocents led astray.

Supporting evidence for Dr Zhu:

See the complainants’ research diary notes from 11th September 2001 to 10 June 2003. These are reproduced as part of Exhibit 19 on the CD ROM, page 4 onwards.

Supporting evidence for Dr Georgiades:

Dr Georgiades was in a very difficult position. He replaced Dr Zhu, following his resignation. At meetings between the remaining authors and the complainant, he came under pressure to maintain a low profile. At the time Georgiades was writing up his PhD under the supervision of Dr Oyadiji. He had very little choice but to do as he was told by the senior authors.

The complainants own health, professional good name and finances have been damaged by the tricks used against him. He is aware that Drs Zhu and Georgiades will have been under similar pressures. They have his sympathy.

Please get back to the complainant if you have any further queries.

Yours sincerely,

![]()

Bill Courtney

Document D1 ends

Comments

1 The embarrassing ignorance of the laws of physics displayed by the authors could have been avoided.

In 2001 Courtney had suggested some simple modifications to the piston and cylinder design that would generate valid results.

Unfortunately pride stopped his Manchester University colleagues from changing their design.

The modified design is described on our Core characteristics web page.

2 It is important to emphasise that the first author of the JEMT paper, Georgiades , should be treated as

“an innocent led astray”. He was on the verge of submitting his PhD under the supervision of Oyadiji and is likely to have come under pressure to conform with fellow fraudsters.

Courtney is aware of this from his personal experience and from that of a Manchester undergraduate student who was tempted to speak out when he found himself sinking into SALi fraud. For details of the undergraduate case CLICK.