Exhibit 37 for the Formal Enquiry Panel

Evidence that Manchester University misled the EPSRC and other funding bodies into believing that Dow insisted on ineffective elastic packaging for SALi being used.

.This document is important because it demonstrates that Dr Turner played an important part in the research fraud. In spite of this, he was allowed to appear as an “independent witness”, testifying on behalf of the scapegoat Dr Oyadiji.

Background notes

Covelle is an elastic packaging material made by Dow Chemicals. It was used as an inner containment bag for SALi samples because it was easy to heat weld. Bur crucially it had be be snuggly packed inside a low stretch outer containment bag for the SALi to absorb impact energy effectively. Bill Courtney supplied his University colleagues with several suitable bags but they were never used.

The following meeting Minutes libel Dow by falsely claiming that

“It was agreed that the use of a textile “containing bag” around the Covelle bag should not be investigated further since this is not acceptable to Dow.”

Nobody from Dow or Cheshire Innovation (Bill Courtney) attended the meeting and there is no evidence to support the claim.

In fact, at a later date, two Dow Chemicals representatives refuted it. (See Section 5 of Document C1.)

In any case, abandoning the containing bag made no engineering sense because the bag was intended to mimic the containment characteristics of the outer plastic bumper facia. Dow’s supposed request for the containment bag to be removed rendered the test results for them useless.

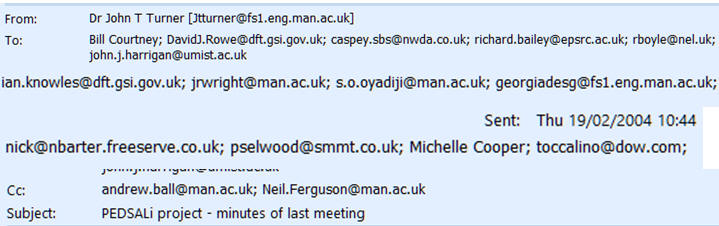

We will present the covering email after the Minutes so that you can read the libelous part first.

Please check our evidence

The email was sent to the EPSRC and other funding bodies, so it should be possible to verify the authenticity of this document using the Freedom of Information Act.

Copies of the email were sent to

The Engineering and Physical Science Research Council (EPSRC)

richard.bailey@epsrc.ac.uk <This email address is being protected from spambots. You need JavaScript enabled to view it.This email address is being protected from spambots. You need JavaScript enabled to view it.>;

(The EPSRC funded the University research)

National Engineering Laboratory

This email address is being protected from spambots. You need JavaScript enabled to view it. <This email address is being protected from spambots. You need JavaScript enabled to view it.>;

The Department for Transport

This email address is being protected from spambots. You need JavaScript enabled to view it. <This email address is being protected from spambots. You need JavaScript enabled to view it.>; This email address is being protected from spambots. You need JavaScript enabled to view it. This email address is being protected from spambots. You need JavaScript enabled to view it. ;

Foresight Vehicle

This email address is being protected from spambots. You need JavaScript enabled to view it. This email address is being protected from spambots. You need JavaScript enabled to view it.

The North West Development Agency

This email address is being protected from spambots. You need JavaScript enabled to view it.

********

The misleading Minutes presented to the above bodies begin here

********

PEDSALi Project

Minutes of the Technical Review Meeting - Tuesday 9th September 2003

Present

Tunde Oyadiji (SOO), George Georgiades (GG), John Harrigan (JH), John Turner (JTT - Chairman).

Apologies were received from Jan Wright, Bill Courtney and Michelle Cooper.

Coverage

The following topics were discussed.

1. Construction of the bags

GG reviewed the different methods of bag construction which he had investigated and described the extensive period of development work which has been necessary. The ensuing discussion covered the method of welding the Covelle sheet into the required form and the techniques adopted for the filling process to achieve a satisfactory and repeatable mix of the beads with the liquid. It was agreed that significant improvements have been achieved.

The mechanical problems which have been encountered include failure of the welds under impact load. These failures occurred at the seams and the clamped ends, according to the length of bag investigated. A tendency for the bag material to suffer plastic (permanent) deformation was also reported.

- - - - - - - Break in original text - - - - - - - -

Bill Courtney comments for the web page reader:

Based on his own work, later verified by Cardiff University, all these mechanical problems would have been avoided if the correct low stretch outer textile bag had been used. The University researchers were warned about this.

- - - - - - - - - - - - - - -

A much improved method of sealing the ends has been developed which incorporates O-rings, internal flanges, and external clamping rings. It was agreed that the use of a textile “containing bag” around the Covelle bag should not be investigated further since this is not acceptable to Dow.

(Text highlighted by Courtney for the web page reader)

With regard to the filling process, this is now achieved under more carefully controlled conditions in which the bag is first packed with the beads. The fill liquid is then introduced at a flow rate which is controlled more precisely than hitherto by a system of valves and a hydrostatic liquid supply tank. So far, only the low viscosity liquid has been used and it is recognised that a more sophisticated liquid filling method (incorporating a heater) may be needed before the more viscous fill liquids can be investigated.

2. Beam testing

It was stated that work on the beams was underway, even though improvements to the construction and filling of the bags can be expected to continue. The performance of bags of length 190, 380, 570 mm (approximately) will be measured. The apparatus for these tests continues to be improved e.g. by the addition of clamps attached to the load measuring system, and by appropriately positioned pressure transducers.

3. Experimental findings

GG (and SOO) presented the results obtained most recently. These were discussed in considerable detail by those present.

NOTE. All these results will be presented at the next PEDSALi Management Meeting on 29th September so are not circulated herewith.

Force versus displacement and pressure versus displacement data characteristics have been obtained for the Newtonian fluid-based SALi. The tests were limited to the lower velocity levels because of the tendency of the Covelle bag to fail at the seam, or distort badly, under impact. Two different sizes of beads were used. Here, there was some indication that the performance between these did indeed differ along the lines suggested earlier by the core characterisation (piston in cylinder) tests.

The following observations were made: -

(i) Good repeatability was obtained.

(ii) The trends appear to follow those established by the core characterisation tests.

(iii) It will be impossible to achieve the number of tests envisaged in the Project Programme produced by Dow (Peter Cate – July 2003) because clamping the same (long) bag cannot be used if we are to achieve repeatability of the test conditions. This means that a separate filled bag will need to be produced for each and every test.

(iv) The availability of Covelle in the form of a seamless tube would be very helpful, particularly in terms of achieving the project timescales.

4. Actions

It was agreed that SOO would approach Dow to request materials, as follows: -

Covelle in tube form or some suitable adhesive

Selection of liquids – with known properties

Beads with controlled sizes – the existing supply is now nearly exhausted.

- - - - - - - - Break in original text - - - - - - -

Bill Courtney comments for the web page reader:

The real reason that the existing supply was "nearly exhausted" was that materials supplied by Dow had mysteriously dissapeared from the University laboratory. But the University reserchers had refused Courtney's requests to call in the police and inform Dow.

When Dow discovered they had been misled by the University researchers they refused to supply replacement materials.

- - - - - - - - - - - - - - -

GG would now concentrate on completing the experiments on the beams and on data reduction. A review of the principal developments is to be given at the next Management Meeting on 29th September 2003.

J. T. Turner

School of Engineering

25th September 2003

*************************

Here is a copy of the the covering email.

Dear Colleague

This message is to inform you that the draft minutes for the last meeting of the Project Management Committee, held on 30th January, have now been completed by Pat Selwood (and approved by me). As agreed at the meeting, the minutes have been placed in a secured location on the Foresight web site.

To gain access to the minutes and accompanying technical information, Committee Members are asked to contact Pat Selwood directly. He will issue a password to allow access.

Pat's email address is This email address is being protected from spambots. You need JavaScript enabled to view it.

Please note that I do not intend to issue these minutes individually to members, unless any problems are encountered. Once you receive a password, you should be able to download the material as required. This new method has been adopted because it makes it possible for everyone to view all of the material relevant to our meetings (both Management and Technical Review). Noting the sensitive nature of some of the material, you may be sure that access will be carefully restricted.

Thanks to Pat and his colleagues at Foresight for taking on this task.

Best wishes.

John

Dr J T Turner

Reader in Engineering

Project Coordinator - PEDSALi Project

*************** Minutes end here *******************

Bill Courtney comments for web page readers

Initially Dr Turner had introduced himself as an independent person appointed by the University.

But, by the time of this email, without the agreement of Dow (who by this time had given up on attending face to face meetings at the University) and under protest from Courtney, Dr Turner had promoted himself to holding the central role in the project as, "Project Coordinator - PEDSALi Project."

This puffing up of his status added credibility to his deception of the funding bodies when he falsely claimed that Dow found the use of the correct low stretch packaging unacceptable. It also allowed him to try and twist Dow's arm into supplying additional materials, even though Dow had been misled about the disappearance of the original supplies.

There was no such role as "Project Coordinator." The nearest thing to it was the role of "Leader partner" and the Department for Transport had appointed Bill Courtney to that role. Click to see proof.

Long term consequences of this deception

Pedestrians will be exposed to a completely unnecessary risk of death and crippling injuries in impact accidents until an open and independent enquiry into what went wrong at Manchester University is held.

Bill wants to see Manchester University thrive. But pedestrian lives are more important than Manchester University's aim of becoming one of the worlds top 25 research institutions.